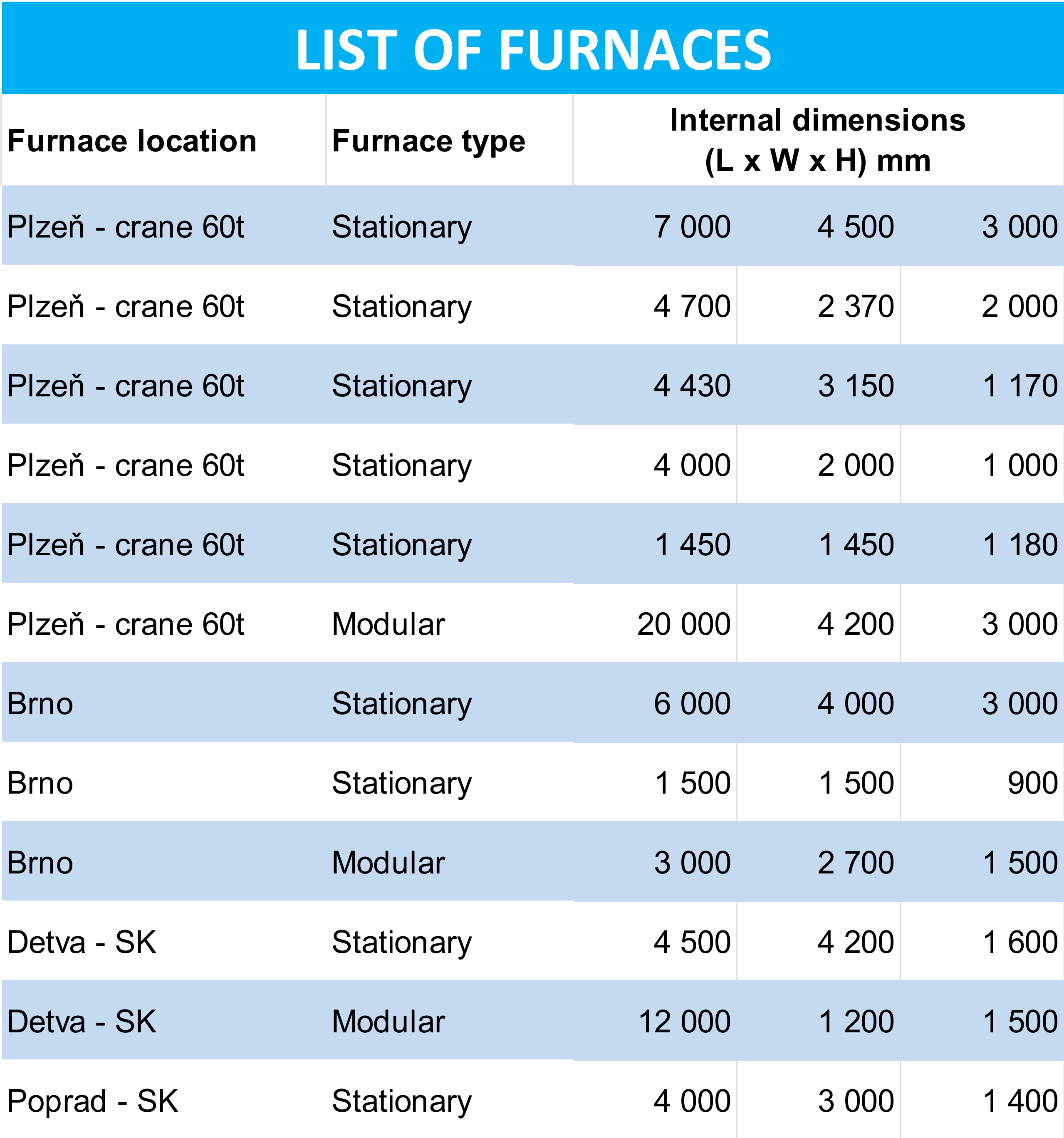

The variability of stationary and modular furnaces in all our plants allows us to treat metal structures and parts of various quality, sizes and weights. Our stationary furnaces are used for up to 7-meter units. A variable modular furnace can be built according to your needs for units of up to 20 meters in length and weighing up to 60 tons.

The main purpose of heat treatment is to improve the properties of steels, cast iron and non-ferrous metals after casting, forging, cutting, machining and welding.

Annealing is performed at temperatures ranging between 100 °C and 1200 °C.

This is followed by free air cooling or regulated cooling in the furnace.

Standard heat treatment processes in furnaces:

Preheating Before Welding

Preheating the metal to be welded slows the cooling rate in the weld area. This may be necessary to avoid cracking of the weld metal or heat affected zone and to encourage hydrogen diffusion from the weld area.

– Temperature: 100–350 °C

– Annealing time: depending on the quality and thickness of the material

Annealing to Relieve Internal Stresses

This process is utilized to relieve internal stresses induced by welding, machining, hot forming, casting or cutting due to uneven rapid cooling. The heating and cooling of metal parts is controlled and progressive.

– Temperature: 440–650 °C

– Annealing time: 1–10 hours

Soft Annealing

The purpose of soft annealing is to produce a soft structure of metal, reduce its hardness and prepare the workpiece for machining and welding. It is used especially for tools steels and some structural alloyed steels before hardening.

– Temperature: 650–790 °C

– Annealing time: 2–8 hours (or more)

Recrystallization Annealing

This annealing process is typically applied to cold-worked metal to produce a new grain structure without going through a phase change. The process removes the results of heavy plastic deformation.

– Temperature: 550–700 °C

– Annealing time: From tens of seconds up to 1 hour

Annealing To Remove Hydrogen

The process is used to prevent internal cracks caused by diffusion hydrogen. It is applied to large-sized products, castings, thick sheet metal and cut shapes.

– Temperature: 600–680 °C

– Annealing time: From tens of seconds up to 1 hour

Normalizing

Normalizing aims to give the workpiece uniform, regular and fine-grained structure with improved hardness. It is generally applied to casting, weldments, cold rolled parts, rolled profiles and sheet metal.

– Temperature: 30 – 50 °C above Ac3, or Acm

– Annealing time: 1 hour – 4 hours

Homogenization

Homogenization is performed to balance the difference in chemical composition and to remove structural imbalances in large-size forgings, castings, and high-alloy steels.

– Temperature: 1 000–1 200 °C

– Annealing time: 10–15 hours (or more)

Solution Annealing

Solution annealing is used to increase the corrosion resistance of CrNi and CrNiMo welded joints in stainless steels. Solution annealing will get rid of unwanted carbides and redistribute elements in the welded structure. The process is followed by rapid air cooling or water quenching.

– Temperature: 950–1 150 °C

– Annealing time: up to 20 minutes

Would you like to know more about annealing? Our technologists will be happy to answer all your questions.